background knowledge

In todays highly developed chip industry, the chip tray serves as a critical carrier in the processes of chip transportation, storage, and processing, with its flatness directly impacting the quality and performance of the chips. Even minor deviations in flatness can lead to issues such as positional shifts, poor contact, or even damage during subsequent processing, thereby affecting the yield and efficiency of the entire chip production line. With the rapid advancement of technology, the emergence of 3D camera technology has brought about unprecedented solutions for flatness inspection of chip trays. Leveraging significant advantages such as high precision, non-contact operation, and high efficiency, it is reshaping the landscape of chip tray inspection.

Camera selection

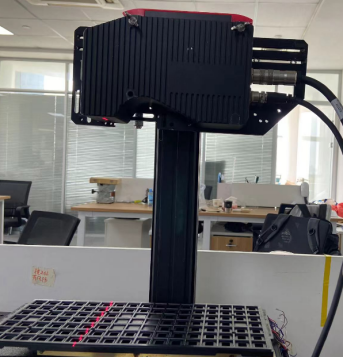

Today we will introduce the application case of Next vision tech LVM25 4 0 line laser 3D camera in manufacturing inspection!

The LVM25 4 03D intelligent sensor from Next vision tech has a full-frame acquisition rate of 2500Hz, which can be set to up to 56000Hz through ROI; it has 1920 physical contour points, and under uniform spacing sampling conditions for depth maps, it can reach up to 4096 points. The products comprehensive performance is at an industry-leading level, making it an ideal choice for high-speed online inspection systems!

surveillance project

Workpiece information

· Material: plastic

· Color: black

· Size: 320 x 135mm

Testing requirements

· The edge step surface of the tray is required to be 0.05mm in plane accuracy

Testing environment and installation method

· Scanning method: the camera is fixed, and the test sample moves along the center line for scanning measurement

· Trigger mode: the encoder is used to trigger and the output is a stable AB difference signal

· Communication mode: TCP/IP Ethernet

Image acquisition effect

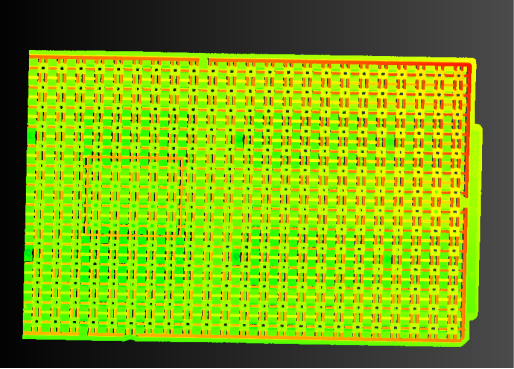

· The picture shows the product One Cloud effect

· The picture shows the products two-point cloud effect

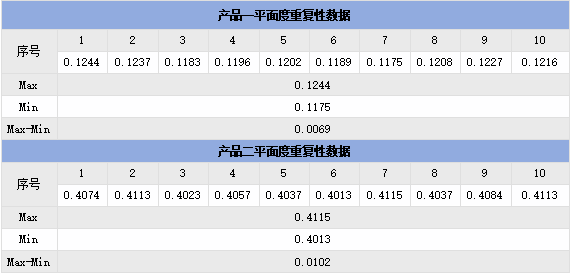

measured data

Test conclusion

· The maximum value of the 10th static maximum repeatability data is 0.0 102mm, which meets the detection requirements of flatness 0.05

2024/12/13

2024/12/13