背景知识

In the field of industrial automation, as a core control device, the quality of industrial control computer parts and the flatness accuracy directly affect the stability and reliability of the entire industrial system. Relying on its advanced three - dimensional imaging technology, 3D cameras provide efficient and accurate solutions for the parts of industrial control computers and flatness detection, which greatly promotes the improvement of industrial production quality.

Camera model selection

Today, I will introduce to you the application cases of Next Vision Tech's LVM2050 line - laser 3D Sensor in the detection of the industrial automation control industry!

The LVM2050 3D intelligent sensor has a full - frame acquisition rate of 340Hz, and can reach up to 10000Hz by setting the Region of Interest (ROI); it has 2048 physical contour points, and can reach up to 4096 points under the condition of uniform spacing sampling of the depth map, meeting the needs of various high - speed and large - batch detection applications. It is a cost - effective 3D intelligent sensor!

Test item

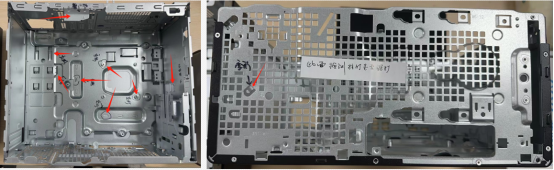

Workpiece Information

·Material: Metal

·Color: Blue, Yellow

·Size: 340mm * 270mm * 140mm

Detection Requirements

1、Detect whether there are black workpieces or not.

2、Detect deformation and presence or absence.

3、Detect the floating height of the blind rivet and the situation of missing riveting.

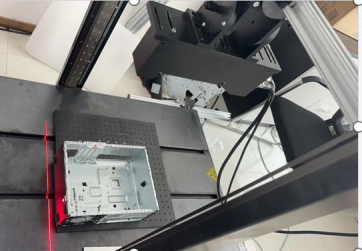

Detection environment and installation methods

·Scanning method: The camera is fixed, and the test sample is scanned and measured by moving along the central straight line.

·Triggering method: Encoder triggering is adopted to output stable AB - phase differential signals.

·Communication method: TCP/IP Ethernet.

Effect of picture - taking

1.Does the black workpiece have a point cloud map

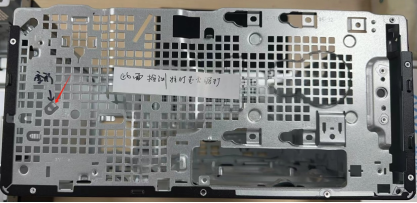

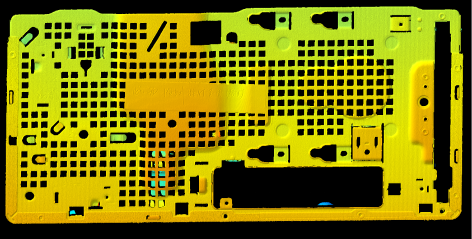

·The figure shows the physical object image and the point cloud image.

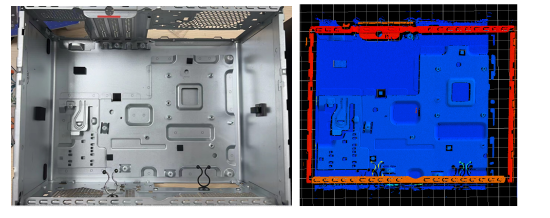

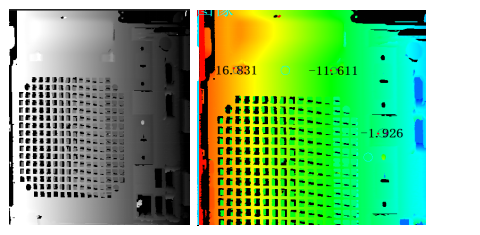

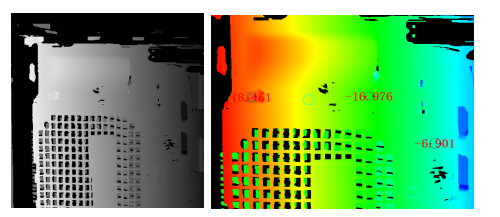

2.Workpiece deformation and the presence or absence of point cloud diagrams.

·The picture is a test picture, and the positions with missing parts or different from the template will be marked with red frames.

·The picture shows the physical object picture and some point cloud pictures.

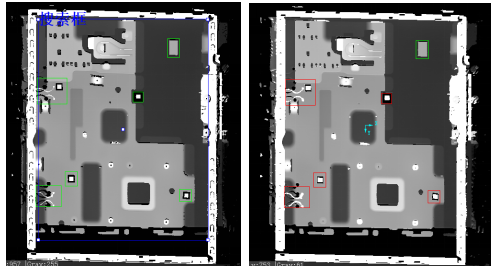

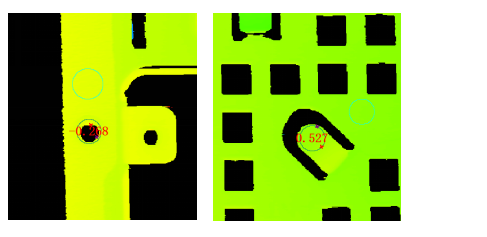

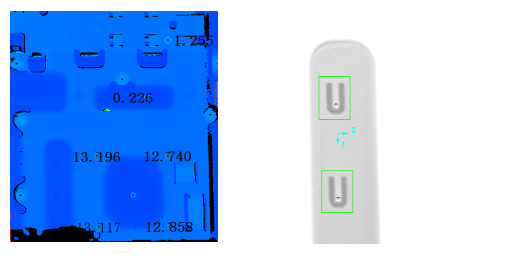

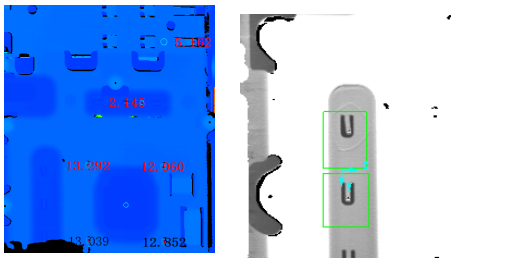

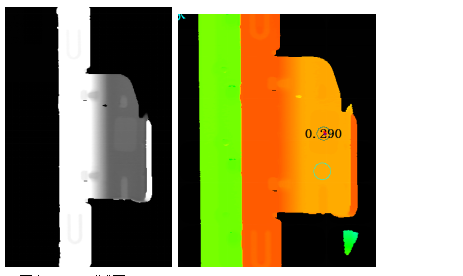

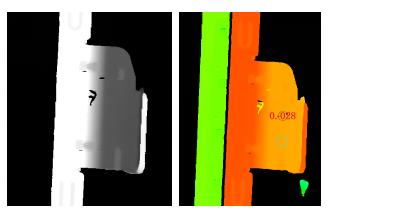

3、Point cloud diagram of workpiece pull - stud floating height and missing pull.

·The picture is the test picture of OK products.

·The picture is the test picture of non - conforming products.

·Picture for OK product test.

·The picture is the test picture of OK products.

·The picture is the test picture of non - conforming products.

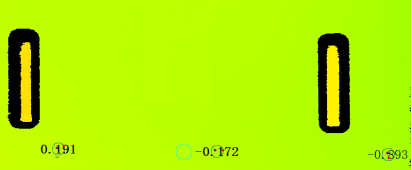

·The picture is the test picture of OK products.

·The picture is the test picture of non - conforming products.

·The picture is the test picture of OK products.

·The picture is the test picture of non - conforming products.

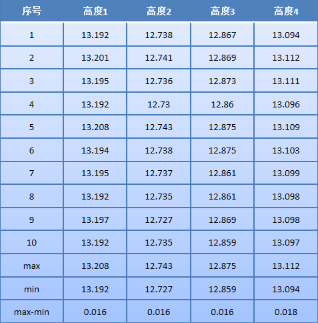

·The table is for the measurement data of the horizontal side.

Detection conclusion

·It can meet the customers' detection requirements, including the presence or absence of black workpieces in the industrial control computer, deformation of the industrial control computer, floating height of pull studs and missing pull.

2025/03/07

2025/03/07