Background knowledge

In the current context of the booming development of the 3C electronics industry, the competition in product performance and quality is becoming increasingly fierce. 3C electronic components often have high integration and precise structures, and even a tiny deviation in surface flatness can cause serious problems. Traditional flatness detection methods have certain limitations in terms of accuracy, efficiency, and adaptability. However, 3D industrial cameras, relying on advanced three-dimensional vision technology, bring a new solution for the surface flatness detection of 3C electronic components and become one of the key technologies to promote the high-quality development of the industry.

Camera Selection

Today, I will introduce to you the application case of the LVM2010 line laser 3D camera of Next Vision Technology in the 3C industry! The LVM2010 3D intelligent sensor has a full-frame acquisition rate of 340Hz, which can reach up to 10,000Hz by setting the ROI; the number of physical contour points is 2,048, and it can reach up to 4,096 points under the condition of uniform spacing sampling of the depth map, meeting the needs of various high-speed and large-volume detection applications. It is a high-cost-performance 3D intelligent sensor.

Test item

· Flatness of product surface

· Determine the position and direction of the product by making points

Product Features

· The workpiece is metallic yellow with slight reflection.

Detection Environment and Installation Method

· Scanning Method: The camera is fixed, and the test sample moves along the central straight line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB differential signal.

· Communication Method: TCP/IP Ethernet

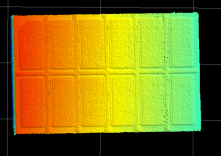

The effect of image capture

·Based on the depth image collected by the camera

·Through image processing, the make points are distinguished to obtain the chip position and the make point position

·Through spot analysis, extract the region for detecting flatness and obtain the height from the hook to the bottom surface

·Through flatness detection, calculate the flatness

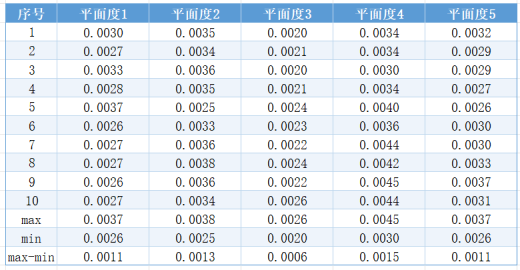

Test Conclusion

· The imaging effect of this solution is relatively complete. The make points are processed by image processing, and the features are clearly visible. The static repeatability within 10 times is within 10μm, meeting the customer's detection requirements.

2025/07/18

2025/07/18