Background knowledge

In the field of consumer electronics manufacturing, laptops, with their characteristics of being lightweight, portable and powerful, have become important tools for people's work, study and entertainment. Consumers' requirements for the quality of laptops are becoming increasingly stringent. Among them, the keyboard, as an important component for direct interaction with users, its quality directly affects the user experience. As a key indicator for measuring the assembly quality of the keyboard, the edge step of the keyboard is crucial for its precise detection. Traditional detection methods have limitations in terms of accuracy and efficiency. The emergence of 3D cameras has brought new solutions for the detection of the edge step of laptop keyboards.

Camera Selection

Today, I will introduce to you the application case of the LVM2050 line laser 3D camera of Next Vision Technology in the 3C industry - the laptop computer segment!

LVM2050 3D intelligent sensor, with a full-frame acquisition rate of 340Hz, which can reach up to 10,000Hz at the highest by setting ROI; the number of physical contour points is 2048 points, and it can reach up to 4096 points at the highest under the condition of uniform spacing sampling of the depth map, meeting the requirements of various high-speed and large-volume detection applications. It is a 3D intelligent sensor with high cost performance.

Test item

·Step Difference Test

·Repeatability Accuracy Requirement: 0.05mm

·Product Size: 240mm * 360mm (Grey Plastic Material)

Detection Environment and Installation Method

· Scanning Method: The camera is fixed, and the test sample moves along the central straight line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB differential signal.

· Communication Method: TCP/IP Ethernet

Image capture effect

·Image effect of the first paragraph

·Point cloud map and brightness map

·The second paragraph of image effects

·Point cloud map and brightness map

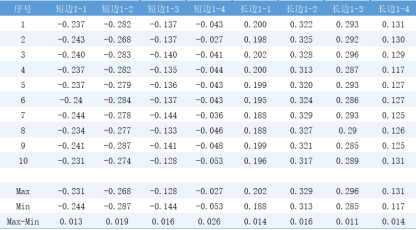

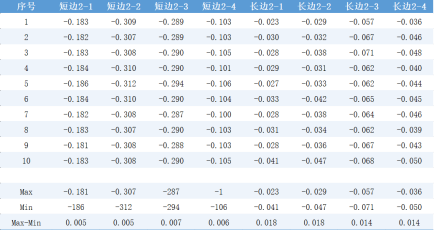

Measurement data

·The first segment of measurement data

·The second set of measurement data

Test Conclusion

· The imaging effect of this solution is relatively complete, and the target area is clearly visible. Considering the repeatability accuracy of the four sides, the maximum static repeatability for 10 times is 0.026 mm, meeting the customer's detection requirement of 0.05 mm.

2025/07/18

2025/07/18