Background knowledge

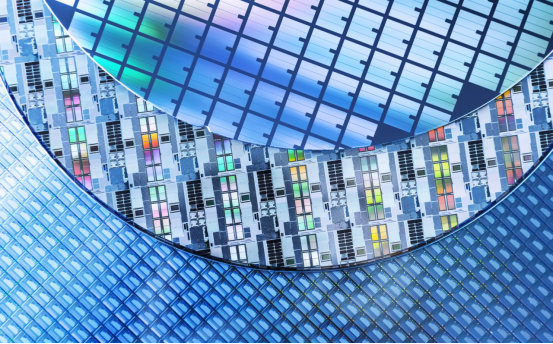

In the current context of the rapid development of the semiconductor industry, chip and device packaging, as a key link in the back end of the industrial chain, has become increasingly important. With the development of electronic products towards miniaturization and high performance, extremely stringent requirements have been put forward for the accuracy, quality and production efficiency of chip and device packaging. As an advanced visual inspection technology, 3D industrial cameras have been widely used in the chip and device packaging process due to their many advantages such as high precision, rapid measurement, and non-contact detection, and have become the core force driving the development of packaging technology and ensuring product quality.

Camera Selection

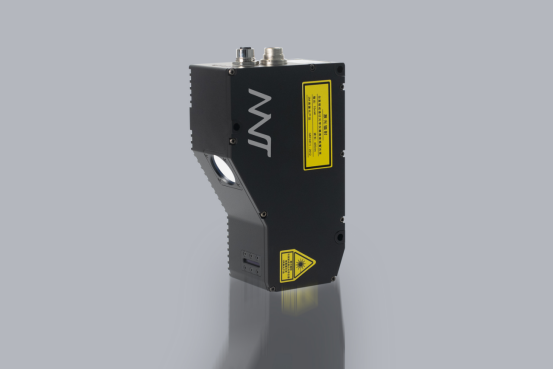

Today, I will introduce to you the application case of the LVM2530 line laser 3D camera of Next Vision Technology in the semiconductor industry!

The LVM2530 3D intelligent sensor has a full-frame acquisition rate of 2500Hz, which can reach up to 56000Hz by setting the ROI; the number of physical contour points is 1920 points, and it can reach up to 4096 points under the condition of uniform spacing sampling of the depth map, which is used for 3D detection of small parts and is an ideal choice for high-speed online detection systems.

Test item

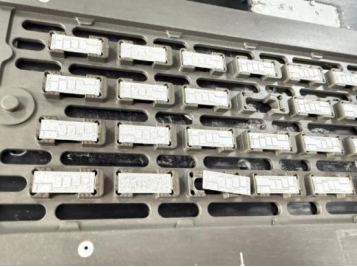

· Detect the tilt height, material shortage, etc. of components in the test fixture.

· Product size: 70mm * 238mm

Detection Environment and Installation Method

· Scanning Method: The camera is fixed, and the test sample moves along the central straight line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB differential signal.

· Communication Method: TCP/IP Ethernet

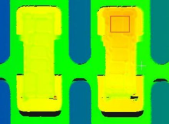

Picture-taking effect

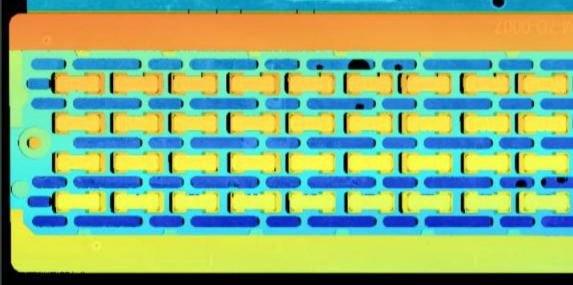

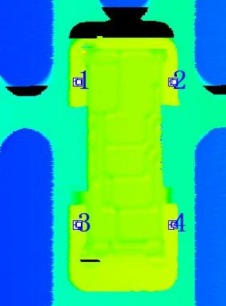

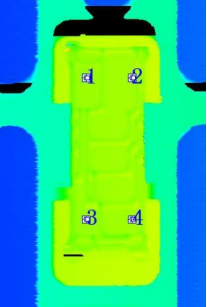

The figure shows a depth map.

· Based on the depth images collected by the camera, processing is carried out.

· Through tools such as pre-processing, model matching, and spot detection height measurement, the products are detected.

· Put 1 piece in for >10 tests, and the repeatability data is stable.

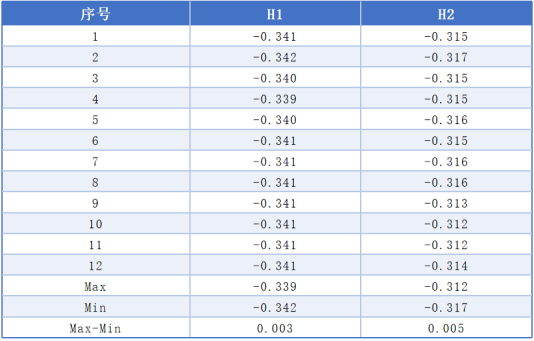

Measurement data

Reference Region of Interest (ROI)

Measurement Region of Interest (ROI)

Data analysis

Measure 12 groups of dynamic data, with a highly repetitive test of 5um

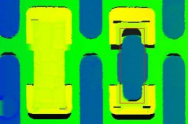

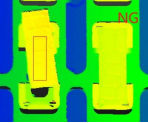

NG effect drawing

Material shortage NG

The materials are tilted and the height is NG

The materials are inclined and the height is NG

Test conclusion

· The imaging effect of this solution is relatively complete. After multiple tests, it can accurately detect inclination, warping and material shortage, meeting the customer's detection requirements.

2025/07/18

2025/07/18