Background knowledge

As a key component for circuit protection, the assembly quality of the fuse module inside the fuse box is of vital importance. The height deviation of the fuse module may lead to poor electrical connection, heat dissipation problems and even potential safety hazards. Traditional detection methods gradually show limitations when faced with the complex internal structure of the fuse box and high-precision detection requirements. With its unique advantages, 3D camera technology provides an innovative and efficient solution for the height detection of the fuse module in the fuse box, becoming a key technical means to improve product quality and production efficiency.

Camera Selection

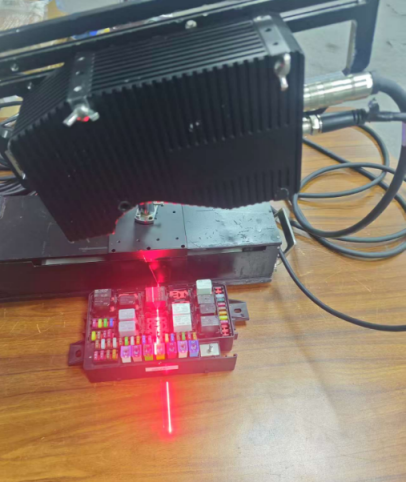

Today, I will introduce an application case of the LVM2540 line laser 3D camera of Next Vision Technology in industrial inspection!

The LVM2540 3D intelligent sensor has a full-frame acquisition rate of 2500Hz, which can reach up to 56000Hz by setting the ROI; the number of physical contour points is 1920 points, and it can reach up to 4096 points under the condition of uniform spacing sampling of the depth map. It is an ideal choice for 3D detection of small parts and a high-speed online detection system.

Test item

· Height and presence/absence of the fuse module in the fuse box

Testing environment and installation method

· Scanning Method: The camera is fixed, and the test sample moves along the central straight line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB-phase differential signal.

· Communication Method: TCP/IP Ethernet

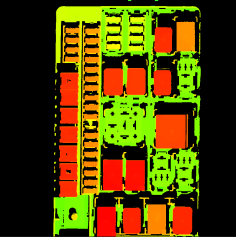

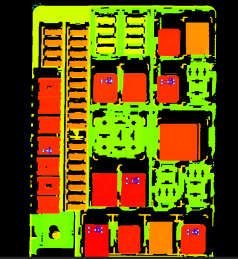

The effect of picture collection

The figure shows a depth map.

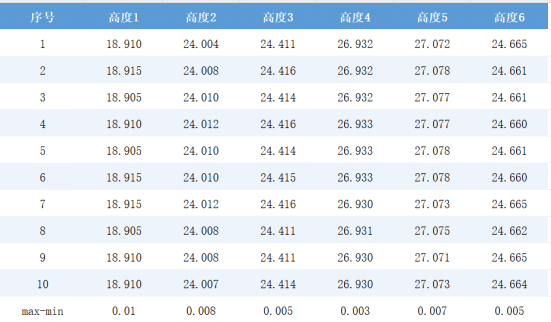

Measurement data

Height detection based on depth map: Place 6 ROI regions (as shown in the figure above) on the surfaces of different fuse modules of the fuse box respectively, and calculate the height of each ROI region to the bottom surface respectively.

Data analysis

6 points, measure 10 groups of dynamic data

Test conclusion

· The imaging effect of this solution is relatively complete, with 10 times of static repeatability. The maximum is 0.01 mm. The height or presence/absence of the fuse module can be judged by the height of the fuse module surface relative to the bottom surface, meeting the customer's test requirements.

· The camera field of view is 99.2 mm at the proximal end to 191.3 mm at the distal end, which can cover the product width.

2025/07/18

2025/07/18