Background knowledge

In the process of automobile manufacturing, the connection and sealing of components are crucial, and the quality of the glue path directly affects the safety, sealing performance and durability of the automobile. Excessive glue path height may lead to assembly interference, while too low height cannot ensure the sealing performance; exceeding the width standard will cause glue waste, and too narrow width will make it difficult to achieve effective connection. Traditional detection methods are difficult to accurately capture these two parameters. With its three-dimensional measurement advantages, the 3D industrial camera has become the key technology to solve the problems of glue path height and width detection, providing a more accurate and efficient solution for the glue path detection of automobile components.

Camera Selection

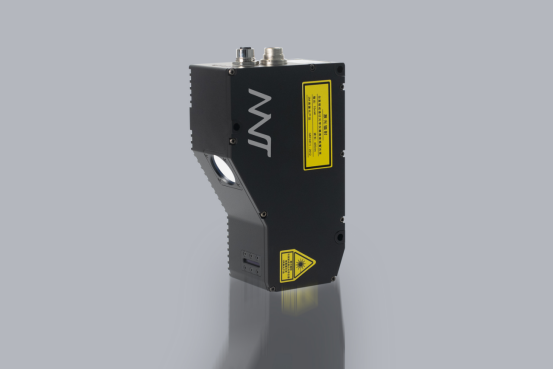

Today, I will introduce to you the application case of the LVM2330 line laser 3D camera of Next Vision Technology in the automotive industry!

The LVM2330 3D intelligent sensor has a full-frame acquisition rate of 1000Hz, which can reach up to 20000Hz by setting the ROI; the number of physical contour points is 1920 points, and the maximum can reach 4096 points under the condition of uniform spacing sampling of the depth map. It is designed specifically to meet the harsh production environment of the factory and is suitable for scenarios of rapid moving object detection.

Test item

· Detect the height and width of the glue path in the parts

· The width of the product is about 75mm

· The requirement for repeatability accuracy is ±0.2mm

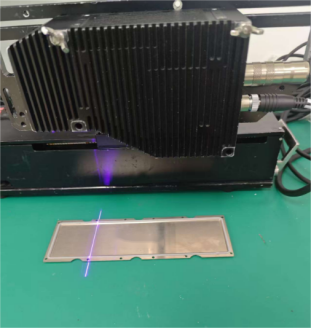

Testing environment and installation method

· Scanning Method: The camera is fixed, and the test sample moves along the central straight line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB-phase differential signal.

· Communication Method: TCP/IP Ethernet

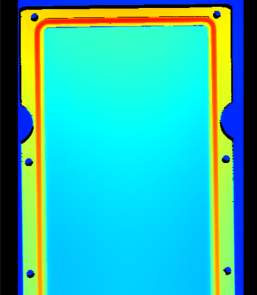

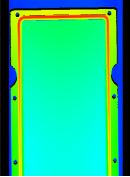

Imaging effect

The figure shows a depth map.

Detection scheme

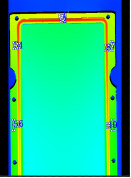

Figure 1

Figure 2

Figure 3

Figure 4

·Based on the depth image collected by the camera (Figure 1), through a pre-processing tool, the depth map is converted into a grayscale map (Figure 2) to perform image feature localization and place the width and height detection point positions (Figure 3 and Figure 4), and calculate the width and height of 5 positions of the glue path respectively.

·The product is fixed to continuously collect 10 images to measure the repeatability data of the width and height of 5 positions of the glue path.

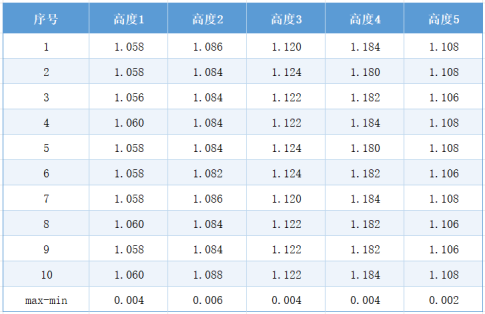

Data analysis

Measure 10 groups of dynamic data. The maximum fluctuation of the height dimension is 0.006 mm, and the maximum fluctuation of the width dimension is 0.0154 mm.

Test conclusion

· The imaging effect of this solution is relatively complete, the characteristic image is clear, and there is no occlusion.

· For the 10 - time static repeatability test, the maximum fluctuation of the height dimension of the data is 0.006mm, and the maximum fluctuation of the width dimension is 0.0154mm, which is within the 0.2mm range required by the customer, meeting the customer's needs.

· The maximum speed of the camera can reach 140mm/s, meeting the customer's needs.

2025/07/18

2025/07/18