Background knowledge

Amid the 3C industry's shift toward precision and intelligent manufacturing, stamped metal components serve as core structural elements in products like smartphone frames, computer cases, camera mounts, and connector terminals. Their dimensional accuracy and surface quality directly determine the assembly compatibility, structural stability, and aesthetic appeal of end products. However, stamping processes are prone to defects such as warping, dents, wrinkles, and edge deformation due to mold wear, material properties, and equipment parameter fluctuations. Traditional inspection methods struggle to meet the high-precision and high-efficiency quality control demands.

With core advantages including stereo perception, high-precision measurement, and rapid response, 3D industrial cameras have become a pivotal technology for addressing the challenge of deformation detection in 3C stamping metal components, driving the industry's quality control transition from spot-checking to comprehensive inspection and prevention.

Camera Selection

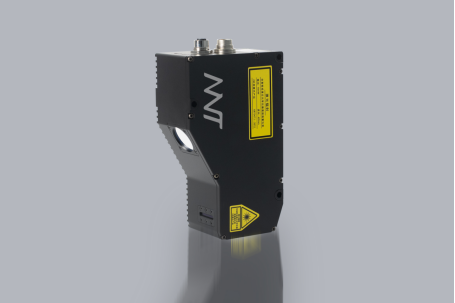

Today, we're showcasing the practical application of Next Vision Tech's LVM2530 linear laser 3D camera in 3C industry inspection!

The LVM2530 3D intelligent sensor features a full-frame acquisition rate of 2500Hz, with ROI settings capable of reaching up to 56000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 0.6μm and capturing every detail, thus meeting the demands of high-precision industrial inspection.

surveillance project

Check the stamping metal deformation and whether the product is deformed in the red circle

Product dimensions: 50mm x 150mm x 80mm (length x width x height); Stamped round hole diameter: 35mm

Precision requirement: The repeatability of the product data is 0.01mm

*The image shows the actual product

Detection environment and installation method

·Scanning method: The camera is fixed in place, and the test specimen is scanned along a central linear path for measurement.

·Triggering method: Encoders are used for triggering to output stable AB phase difference signals

·Communication method: TCP/IP Ethernet

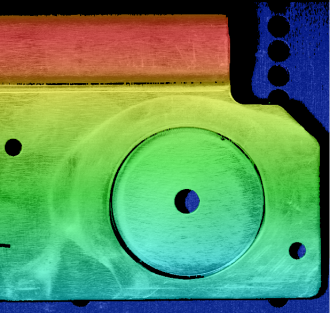

Image capture effect

*The image is a depth map

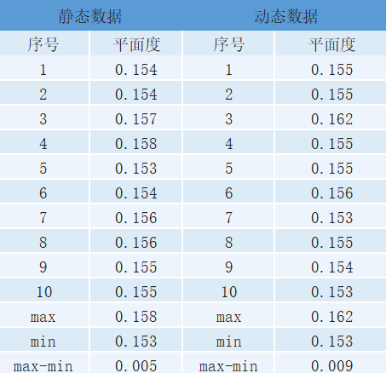

measured data

Figure 1

Figure 2

Figure 3

Figure 4

·Depth image captured by the camera (Figure 1)

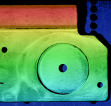

·Through preprocessing, product positioning is performed, followed by selection of the four-side calibration plane (Figure 2)

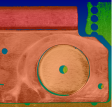

·Ten points were selected from the corrected image to calculate flatness (Figure 3)

·Repeated injection of the same product 10 times, dynamic repeatability <0.01mm (Figure 4)

DA

*10 dynamic measurements with repeatability within 0.01mm

Test conclusion

·This solution delivers high-definition images, with the LVM2530 camera capable of detecting product deformation. The product's repeatability data is within 0.01mm, fully meeting customer requirements.

·Camera speed: This test achieves a speed of 260mm/s

·Camera field of view: 55.4–90.5 mm, covering the detection area

2025/12/26

2025/12/26