Tire is an important part of the automobile, its manufacturing process is complex, in the whole manufacturing process, there are strict quality requirements. In addition to fine appearance detection, a small number of tires will have some defects; such as unqualified size, scratches, bulge, etc.; in some processes, tire pattern detection and DOT character identification, which require 3D visual intervention to overcome many disadvantages of manual detection, and improve its accuracy and work efficiency.

Today for you to introduce the next vision tech LVM 2040 camera in the tire industry 3D vision application case! LVM 2040 Line laser 3D camera model is comprehensive, meet the requirements of various high-speed and mass detection applications; can provide 340Hz full frame acquisition rate, physical contour points 2048 points, depth map uniform spacing sampling maximum 4096 points; Gigabit Ethernet transmission, meet the requirements of multiple scenarios.

一、Ttread section size testing

Customer requirements: measure the tread thickness outline, total width, shoulder width, medium width, shoulder thickness, medium thickness and other key dimensions, keep abreast of the change of tread size at any time, and control the product quality

Product model number: LVM2040

Application challenge: many types of tire material, material surface state difference

High-precision and large-format detection requires multi-camera splicing

Need to customize the camera view and Angle

Drawing effect

(Physical picture) (dot cloud map)

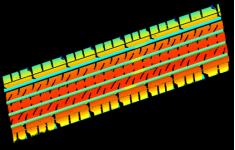

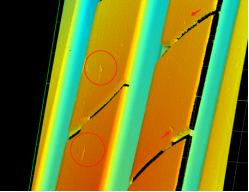

二、Taper cross-section defect detection

Customer requirements: in the tire tread and side wall detection of a variety of small drums, dents, scratches, etc., requiring sub-millimeter level accuracy and reliability

Product model number: LVM2040

Application challenge: there are many fetal types and high imaging quality requirements

The speed beat is faster

Drawing effect

(Physical picture) (dot cloud map)

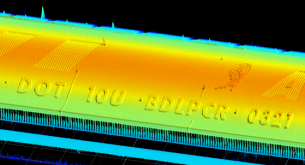

三、Fetface DOT code identification

Customer requirements: By scanning the tire, quickly generate a height map, identify the characters on the tire side wall

Product model number: LVM2040

Application challenge: Complex tire surface patterns

Fast speed and beat, and the positioning accuracy requirements are high

Data interaction with various information systems of the factory

Drawing effect

(Physical picture) (dot cloud map)

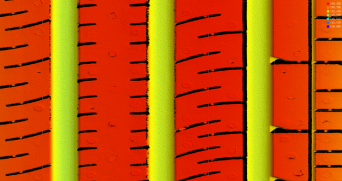

四、Finished tire decorative pattern detection

Customer demand: Check whether the pattern is defective

Product model number: LVM2040

Application challenge: the recognition degree of the black shading on the tire surface is low

Drawing effect

(Physical picture) (dot cloud map)

五、Test conclusion

The LVM 2040-ray laser 3D camera determines the tread profile, total width, shoulder width, tread defects, DOT code identification and tire pattern detection.

Testing value: save manual testing, replace coordinate sampling inspection, realize automatic testing, improve product quality and consistency of testing results, reduce material waste and rework.

About Us

Founded in 2017, Next Vision Tech is a high-tech enterprise integrating industrial visual product design, research and development, production, sales and service. The company focuses on the underlying algorithm development and hardware implementation of industrial vision products, and has a complete set of software and hardware technologies with independent intellectual property rights. The goal is to become the world's leading vision sensor company.

▲ In the field of intelligent manufacturing

The LVM (Laser Vision Measurement) series 3D intelligent sensor developed by Next Vision Tech hardens the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement. Its repeatability accuracy reaches 0.1 micron. The performance index of the product exceeds that of foreign counterparts and can be replaced by imports.At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage and other fields.

2023/04/25

2023/04/25