background knowledge

As a key component of the internal air purification of the car, the existence of the edge burr may destroy the sealing of the filter paper, leading to the unfiltered air and pollutants entering the compartment, affecting the air quality in the cockpit, and then affecting the health and driving safety of passengers. The 3D wire laser camera can accurately detect and quantify the burr size, ensure the sealing effect of the filter element, and maintain the efficient operation of the air conditioning system.

Camera selection

Today for you to introduce the application of LVM2060 line laser 3D camera in the automotive industry detection!

The LVM 2060-line laser 3D camera is a ultra-high speed 3D intelligent sensor, which can provide 340Hz full frame acquisition rate, the physical profile is 2048 points, and the depth map is up to 4096 points, the proximal view range (FOV) is 250mm, and the distal view range (FOV) provides the best target for 236.4mm to meet the requirements of various high-speed and mass detection applications.

Deburr detection at the filter element edge

requirement analysis

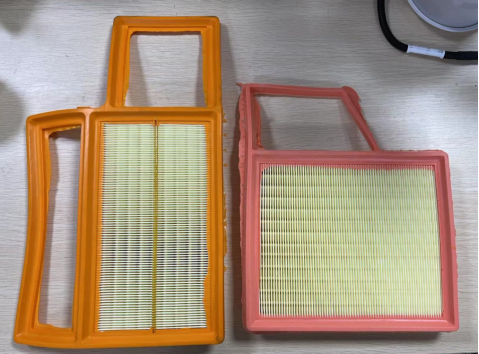

· Material: plastic

· Size: maximum length 600mm; maximum width 400mm

Test requirements

· Precision requirement: 0.5mm

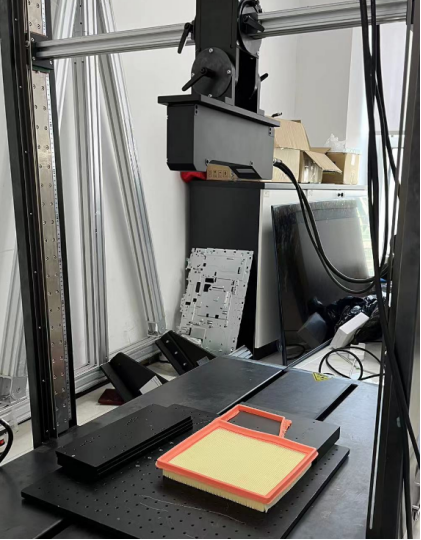

Detection environment and installation method

· Environment Description: After the camera is fixed, the product is measured in a straight line along the center

· Acquisition trigger mode: encoder trigger

· Communication: TCP / IP

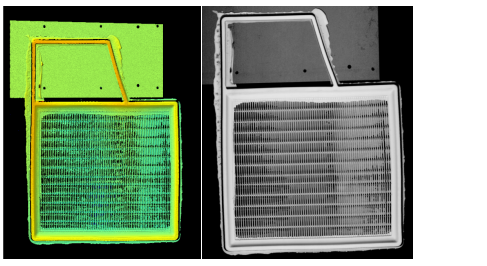

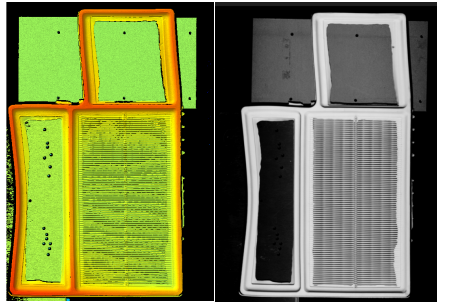

Drawing effect

Drawing effect 1 (point cloud map and brightness map)

Drawing effect 2 (point cloud map and brightness map)

Test conclusion

· The LVM 2060-line laser 3D camera of Next vision tech can meet the customer's measurement accuracy of 0.5mm

· Testing value: Improve manufacturing efficiency, reduce costs, and promote the technological progress of the industry

About the next view

Founded in 2017, Next vision tech is a high-tech enterprise integrating the design, research and development, production, sales and service of industrial vision products. The company focuses on the underlying algorithm development and hardware realization of industrial vision products, with a full set of independent intellectual property rights, to become the most reliable vision sensor leader as the goal.

▲ Research on vision technology · serve Made in China

The LVM series 3D intelligent sensor developed by Vision hardening the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement. Its repetition accuracy reaches 0.1 micron, and the performance index of the product exceeds that of foreign counterparts, which can realize import substitution. At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage processing and other fields.

2024/07/05

2024/07/05