Background Knowledge

In the automotive industry, PIN pins as key components of connectors, the precise detection of their height and positional accuracy is crucial for ensuring the reliability and stability of automotive electrical systems. With the development of automotive manufacturing towards intelligence and high precision, traditional inspection methods can no longer meet production needs. Due to its high precision and efficiency, 3D camera inspection technology has been widely applied in the detection of PIN pin height and positional accuracy.

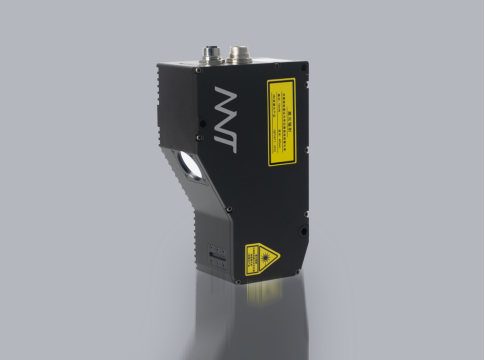

Camera selection

Today we will introduce the application case of Next vision tech LVM25 3 0 line laser 3D camera in automotive industry inspection!

The LVM25 3 03D intelligent sensor from Next vision tech has a full-frame acquisition rate of 2500Hz, which can be set to up to 56000Hz through ROI; the number of physical contour points is 1920 points, and under uniform spacing sampling conditions for depth maps, it can reach up to 4096 points. The products comprehensive performance is at an industry-leading level, making it an ideal choice for high-speed online inspection systems!

Testing requirements

· Measure the height from PIN needle to plastic surface with repeatability of less than 0.1mm

· Measure PIN pin spacing with repeatability of less than 0.1mm

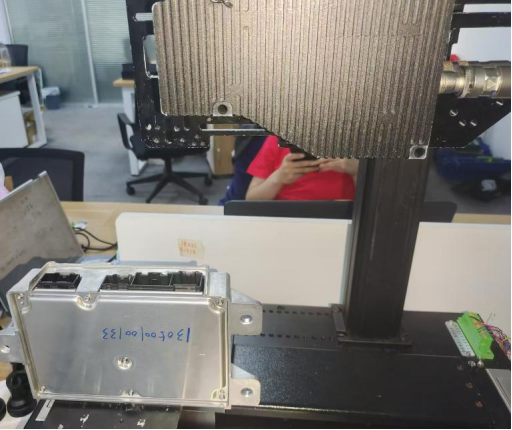

Testing environment and installation method

· Scanning method: the camera is fixed, and the test sample moves along the center line for scanning measurement

· Trigger mode: the encoder is used to trigger and output stable AB difference signal

· Communication mode: TCP/IP Ethernet

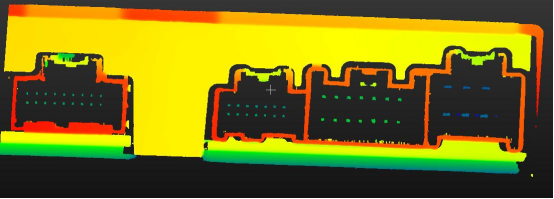

Image acquisition effect

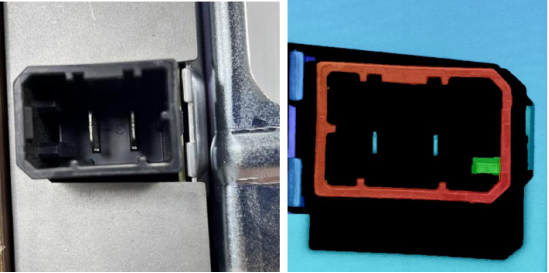

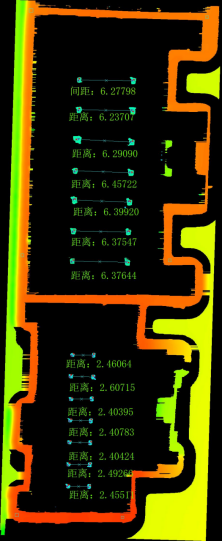

* The figure shows the effect of point cloud

* The figure shows the effect of physical image and point cloud image

measured data

Test sampling point 1

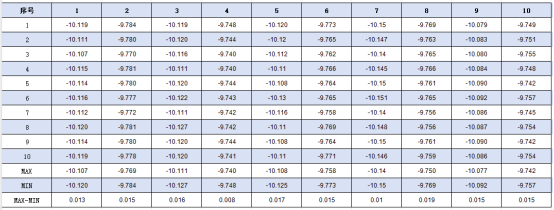

Reproducibility data 1

· Measure the distance between two PINs, with a maximum deviation of 0.011mm in 15 repetitions

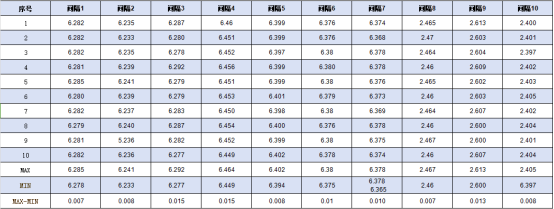

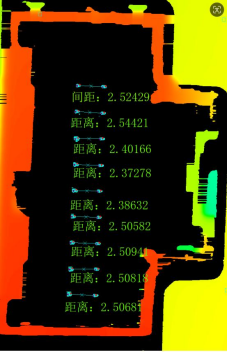

Test sampling point 2

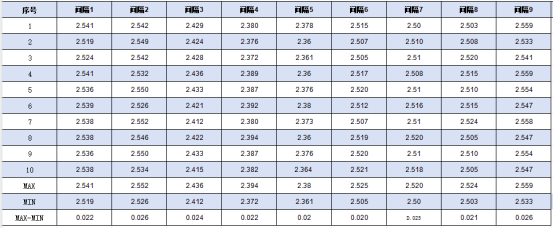

Reproducibility data 2

·The maximum deviation of PIN height repeatability is 0.018mm, and the maximum deviation of PIN spacing is 0.0 2 1mm

Test sampling point 3

Reproducibility data 3

· The maximum deviation of 10 repetitions is 0.019mm and the maximum deviation of interval is 0.0 26 mm

Test conclusion

· The maximum deviation of repeatability of 10 test data is 0.019mm, and the maximum deviation of interval is 0.026mm, which meets the requirements of customers

2024/12/20

2024/12/20