Background knowledge

In the field of 3C product manufacturing, the refinement level of the electronic assembly process is constantly rising. As a commonly used buffer, sealing, and insulating material, the installation height accuracy of foam in electronic devices has an important impact on the performance and reliability of products. Traditional detection methods are difficult to meet the current demand for high-precision and high-efficiency detection of foam height, and 3D detection technology has emerged, bringing innovative solutions to the industry.

Camera Selection

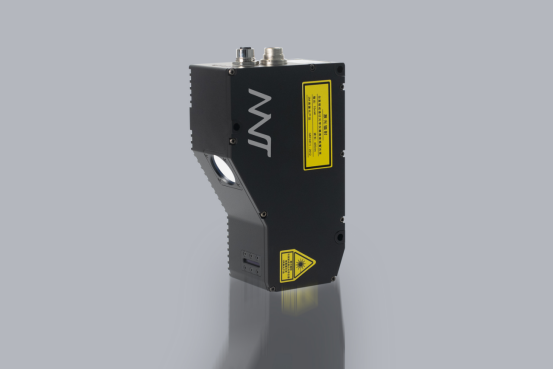

Camera Selection Today, we will introduce an application case of the LVM2530 line laser 3D camera of Next Vision Technology in the 3C industry!

The LVM2530 3D intelligent sensor has a full-frame acquisition rate of 2500Hz, which can reach up to 56000Hz by setting the ROI; the number of physical contour points is 1920 points, and it can reach up to 4096 points under the condition of uniform spacing sampling of the depth map. It is ideal for 3D detection of tiny parts and is an ideal choice for high-speed online detection systems.

Test item

· Product height detection

Testing environment and installation method

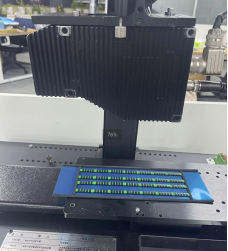

· Scanning Method: The camera is fixed, and the test sample moves along the center line for scanning measurement.

· Triggering Method: Encoder triggering is adopted to output a stable AB differential signal.

· Communication Method: TCP/IP Ethernet

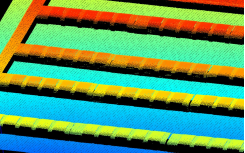

Imaging effect

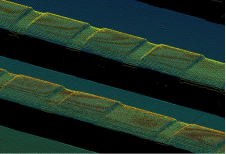

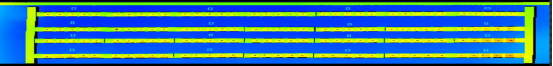

Image processing

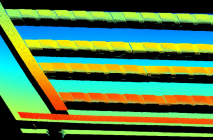

The figure shows the point cloud map of wrinkles, imprints, and edge wrinkles.

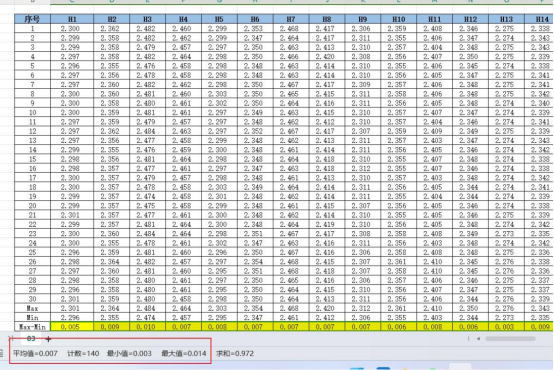

Measurement data

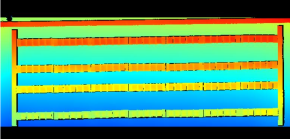

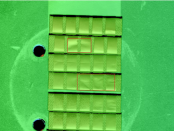

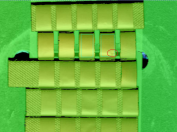

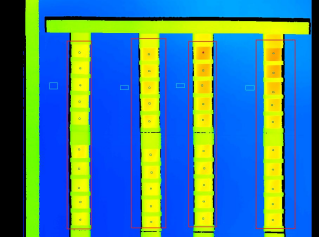

*The figure shows the test points, and each piece of foam has a ROI measurement area.

The red area in the figure is the measurement area of the foam. A total of 140 ROI1 areas are established in the foam area, and 16 ROI2 areas for the reference plane are established in the bottom blue film area to calculate the height of each piece of foam.

Data analysis

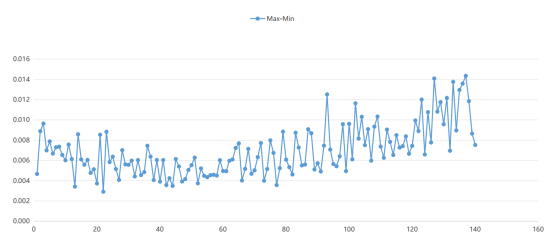

140 points, measure 30 groups of dynamic data, with a maximum repeatability of 0.014 mm

Test conclusion

· The imaging effect of this solution is relatively complete, and the static repeatability within 30 times is within 0.014mm, meeting the customer's test requirements.

2025/07/18

2025/07/18