Background knowledge

In modern footwear manufacturing, the sole—being the core functional component—directly determines product comfort, durability, and safety. For decades, sole inspection has been constrained by traditional methods' limitations, including inefficiency, high error rates, and labor-intensive processes. The integration of 3D cameras and robotic arms has now provided a game-changing solution to overcome these challenges.

When the 3D camera and the manipulator are coordinated, they form a closed-loop system of "perception, decision-making and execution". This fusion mode of "vision + mechanism" completely changes the passive situation of traditional inspection and gives the sole inspection new characteristics of automation, high precision and high efficiency.

Camera Selection

Today, we're showcasing the practical application of Next Vision Tech 's LVM2750 linear laser 3D camera in the footwear manufacturing industry!

The LVM2750 3D smart sensor features a full-frame 1200Hz capture rate, with ROI settings supporting up to 10,000Hz. This industry-leading 4K line laser camera effortlessly meets high-precision inspection demands, delivering exceptional speed and accuracy.

surveillance project

· Locate the raised edge of the sole as the guiding point for the robotic arm

· Product dimensions: 270mm (length) × 90mm (width) × 40mm (thickness)

· Precision requirement: repeatability of 0.1mm

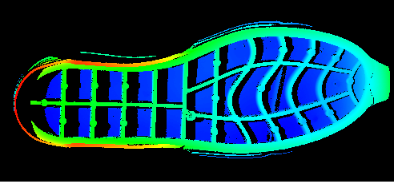

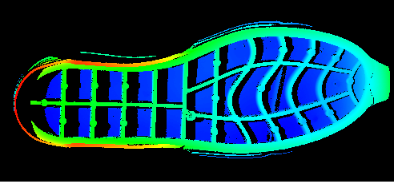

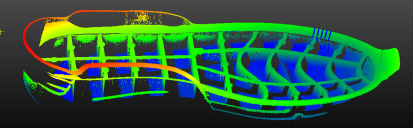

*Product image

Check the environment and installation method.

·Scanning method: The camera is fixed, and the test sample is scanned along a central straight line.

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

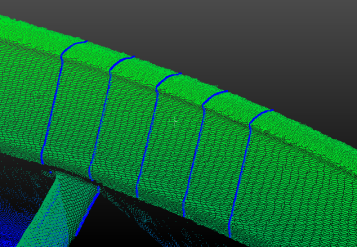

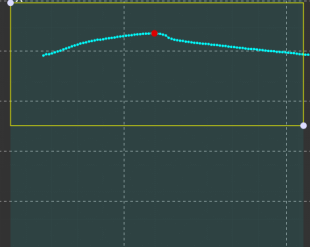

Image capture effect

measured data

*Figure 1: 3D line scan image effect

*Figure 2: Point Cloud Effect

*Figure 3: Software detection

*Figure 4 shows the detailed effect

·Based on the depth image captured by the camera, the product is initially positioned

·At regular intervals, the system detects the product's highest point and transmits the XYZ coordinates of each peak to the robotic arm.

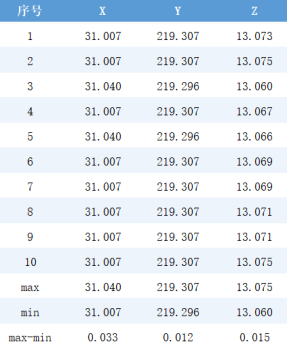

·The static repeatability was verified 10 times in the experiment, and the data was within 0.1mm

DA

*10 static measurements, Z-axis height repeatability within 0.1mm

Test conclusion

·This solution delivers comprehensive imaging with high-definition feature images. The LVM2750 camera accurately measures product contour points with detection accuracy below 0.1mm, fully meeting customer specifications.

·The X-axis resolution of the camera ranges from 23.1 to 30.9 μm, with a maximum testing speed of 37 mm/s

· Vision 96.8~126.5mm, a single scan can completely cover the product

2025/11/14

2025/11/14