Background knowledge

In today's fiercely competitive smartphone photography market, camera modules—key components that directly determine imaging quality—require precision assembly. The critical edge profile difference (height variations between parts like lens mounts, filters, and sensor substrates) is a key factor affecting both assembly accuracy and light transmission. Exceeding industry standards not only causes assembly slippage and compromised sealing but may also lead to optical path deviations, resulting in blurry photos and glare. Given the limitations of traditional inspection methods, 3D cameras have emerged as the breakthrough technology to overcome this detection bottleneck.

Camera Selection

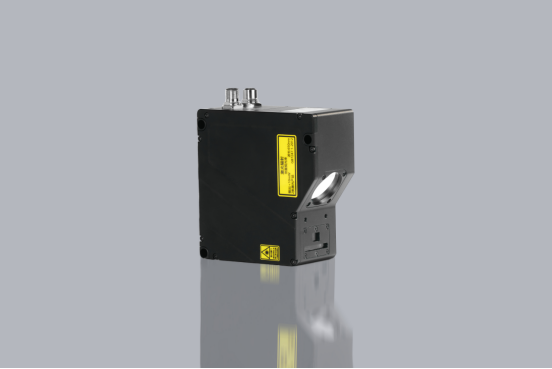

Today, we're excited to showcase the LVM3510 linear laser 3D camera, a new addition to Next Vision Tech's LVM3000 series, and its real-world applications in the 3C industry!

The LVM3510 3D intelligent sensor features a full-frame 2500Hz acquisition rate, with ROI settings supporting up to 56000Hz. Its 0.2-micron repeatability and high dynamic range imaging ensure flawless detail capture. The ultra-high-speed acquisition enables cutting-edge inspection in industrial high-speed scenarios.

surveillance project

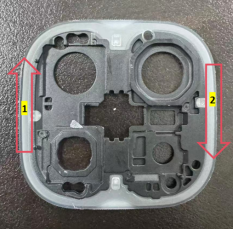

·Detection requirement: product edge to top surface segment difference

·Product dimensions: 45mm in length, 45mm in width, 45mm in height, and 3mm in thickness

·Product tolerance: ±0.05mm

*Image shows the actual product

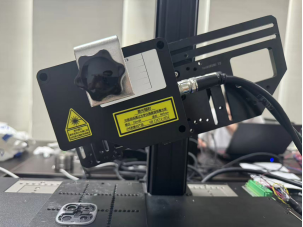

Detection environment and installation method

·Scanning mode: The camera is fixed, or the single camera is installed at a 18° tilt, and the camera moves linearly relative to the workpiece for scanning

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

*Motion description: As shown in the left figure, products 1-2 indicate the camera's movement path and scanning direction, with two scans in total.

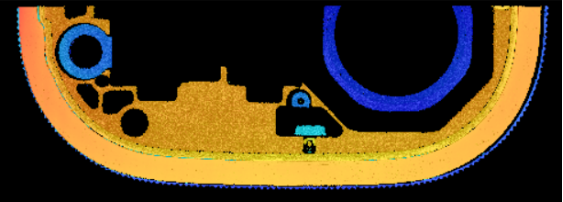

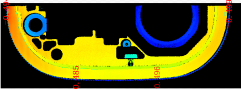

Image capture effect

*The image shows a point cloud

measured data

Figure 1 Figure 2

Figure 1 Figure 2

·Based on the depth image of the point cloud captured by the camera, the point cloud is observed to have no obvious noise.

·Through preprocessing, the line-line intersection forms a positioning line between them

·Use the upper surface area of the product as the reference to measure the edge-to-surface segment difference

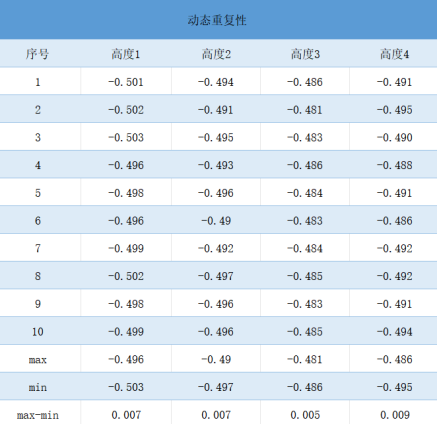

·The experiment was repeated 10 times in total

·The product's repeatability is <0.01mm after 10 tests

DA

*Measure 10 sets of dynamic data. The maximum static repeatability is 0.005mm, and the maximum dynamic repeatability is 0.009mm.

Test conclusion

This imaging solution delivers comprehensive results with clear, unobstructed feature images.

The LVM3510 camera accurately measures the distance from product edges to the upper surface.

·Repetitive data is 0.009mm, meeting customer requirements

·The speed of this test can reach 110mm/s

2025/09/12

2025/09/12