Background knowledge

As the "nerve center" of a vehicle, the automotive controller's PIN pins require high consistency in height and precise positioning to ensure reliable electrical connections. In production, any deviation in pin height or position can lead to minor issues like poor solder joints or contact failures during reflow soldering, or severe consequences such as controller malfunction and even traffic accidents.

However, traditional inspection methods have long been constrained by technical limitations: manual visual inspection is not only inefficient but also fails to detect micron-level height deviations and achieve 100% defect coverage. In contrast, 3D camera inspection technology, with its high precision, efficiency, and stability, has emerged as the core solution for detecting the height and positional accuracy of automotive controller PIN pins, effectively overcoming the technical challenges of conventional inspection methods.

Camera Selection

Today, we're excited to showcase the automotive application of the LVM3330 line laser 3D camera, a new addition to Next Vision Tech's LVM3300 series!

The LVM3330 3D smart sensor features a full-frame 1200Hz acquisition rate, with ROI settings supporting up to 18000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 1.6μm and capturing every detail, making it ideal for high-precision industrial inspection.

surveillance project

·Inspection requirements: PIN needle height and positional accuracy

·Product tolerance dimensions: height tolerance 0.3, position tolerance 0.1

·Camera accuracy: Z-axis repeatability 0.06mm; XY-axis repeatability 0.05mm

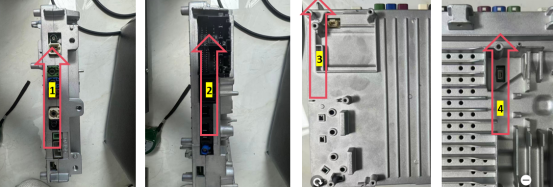

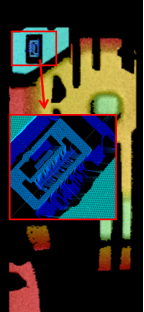

*Image shows the actual product

Check the environment and installation method.

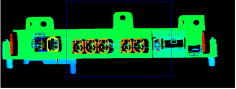

·Scanning method: The single camera is installed at a 11° tilt, and the test sample is scanned along a central straight line.

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

As shown in the figure above, products 1-4 represent the camera's movement path and scanning direction, with four scans in total.

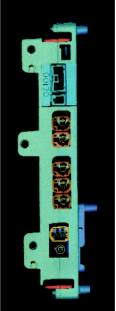

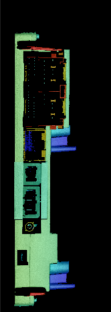

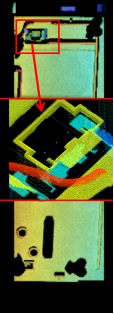

Image capture effect

measured data

·Based on the depth image of the point cloud captured by the camera, the point cloud shows no obvious noise.

·Through preprocessing, the intersection points of lines form a straight line for positioning

·Use the upper surface area of the product as the reference to measure the edge-to-surface segment difference

·Measure the Pin distance from the XY position

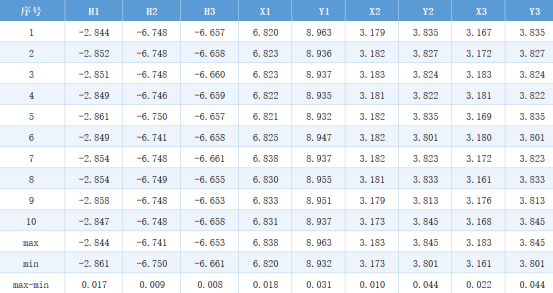

·The experiment was repeated 10 times in total

DA

static repetitiveness

*10 sets of static data were measured, with a maximum Z-direction displacement of 0.009mm and a maximum XY-direction displacement of 0.019mm

dynamic repetitiveness

*The maximum Z-axis measurement across 10 dynamic datasets was 0.017mm, while the XY-axis measurement reached 0.044mm.

Test conclusion

·This solution delivers comprehensive imaging with clear feature images, enabling precise measurement of product PIN needle height and positional accuracy using the LVM3330 camera.

·The Z-axis repeatability is 0.017mm, and the XY-axis repeatability is 0.044, which can reliably detect the product's segment difference and meet the 0.05mm testing requirement.

·The theoretical maximum speed of this test can reach 72mm/s

2025/09/26

2025/09/26