Background knowledge

In the precision manufacturing chain of semiconductors, IC trays function as the "transport armor" between wafers and chips, where structural integrity directly determines device safety. Reinforcing ribs, serving as the core load-bearing structure, achieve a "rigid-flexible balance" through honeycomb or grid designs. Installation defects in these ribs may cause substrate bumps to develop foreign particles or bridge effects, ultimately leading to die bonding short circuits.

3D industrial cameras, with their 3D data acquisition capabilities, robust anti-interference performance, and intelligent analysis functions, have fundamentally resolved the industry's pain point of reinforcing rib detection in IC trays. From the immediate benefit of preventing single-wafer scrapping to the long-term value of optimizing the entire process, 3D vision technology has become an indispensable "precision benchmark" in semiconductor smart manufacturing. In the future, it will play a core supporting role in the quality control system of advanced packaging.

Camera Selection

Today, we're excited to showcase the LVM3040 line laser 3D camera, a new addition to Next Vision Tech's LVM3000 series, and its real-world applications in the semiconductor industry!

The LVM3040 3D smart sensor features a full-frame 600Hz acquisition rate, with ROI settings supporting up to 10,000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 3μm and capturing every detail, making it ideal for high-precision industrial inspection.

surveillance project

·Inspection requirement: Check for reinforcing ribs in the IC tray

·Product Information: Black injection-molded part

·Camera accuracy: Clear image with no noise

* shows the actual product

Check the environment and installation method.

·Scanning method: The camera is fixed, and the test sample is scanned along a central straight line for measurement.

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

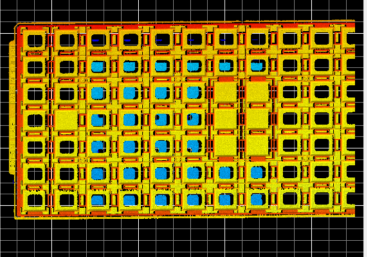

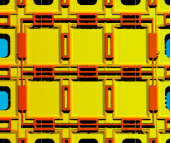

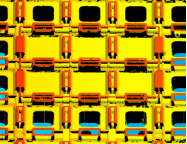

Image capture effect

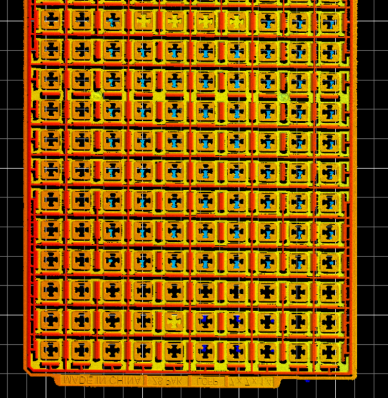

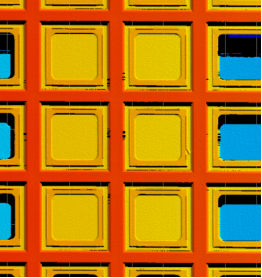

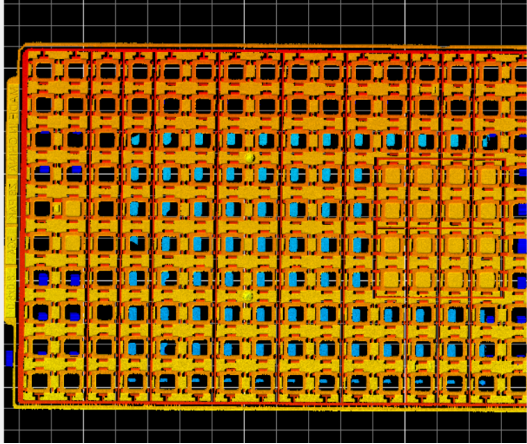

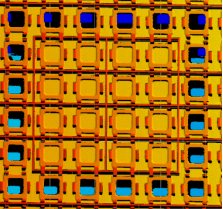

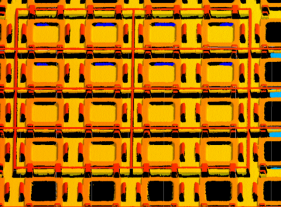

Image Effect 1

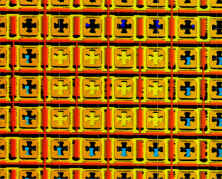

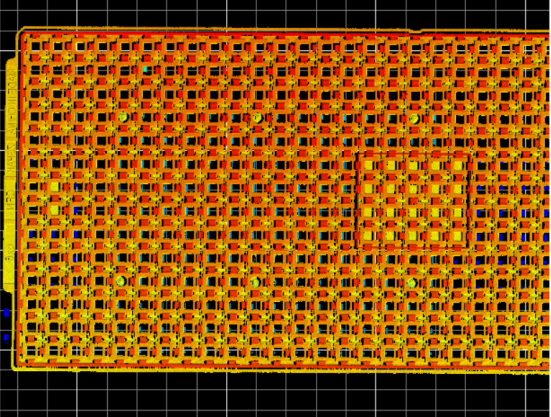

Image Effect 2

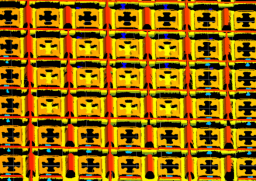

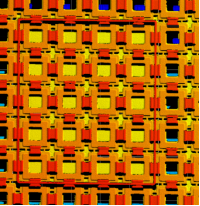

Image Effect 3

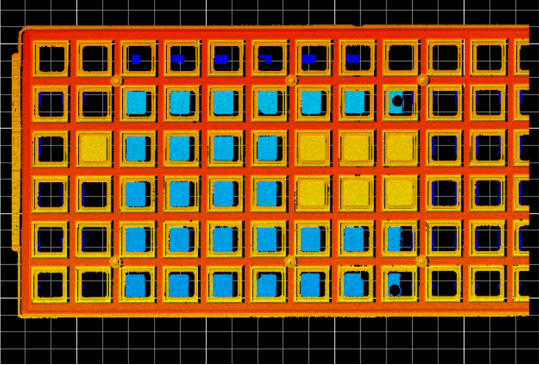

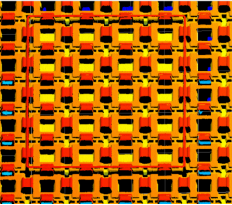

Image Effect 4

Image Effect 5

Test conclusion

·This solution delivers comprehensive imaging with sharp feature images. The LVM2040 3D smart camera fulfills customer inspection requirements, ensuring no data loss or noise in critical areas.

·The theoretical maximum speed of this test can reach 60mm/s

2025/10/17

2025/10/17