Background knowledge

As the core sector of the global tech industry, the 3C industry updates its products at a monthly pace. Interface pins, serving as the 'bridge' for device connectivity, have their flatness precision directly determining product quality and user experience. A mere 0.01mm deviation in flatness can become a 'hidden killer' —a single pin with such a slight height discrepancy may cause smartphone charging interruptions, data transmission failures, screen flickering, or image distortion.

The traditional manual inspection is inefficient, the contact measurement is easy to cause secondary damage, and the 2D vision is unable to capture the Z-axis information and frequently missed. In this context, the 3D industrial camera with the advantages of high precision, high speed and high stability has become the core technical solution to solve the detection problem.

Camera Selection

Today, we're excited to showcase the LVM3320 linear laser 3D camera, a new addition to Next Vision Tech's LVM3300 series, and its real-world applications in the 3C industry!

The LVM3320 3D smart sensor features a full-frame 1200Hz acquisition rate, with ROI settings supporting up to 18000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 1.2μm and capturing every detail, making it ideal for high-precision industrial inspection.

surveillance project

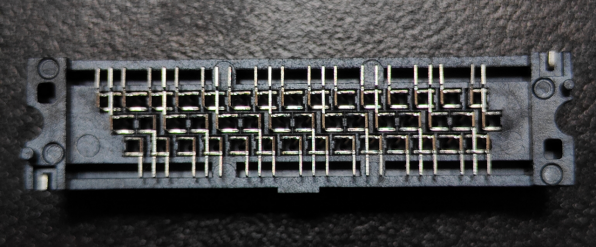

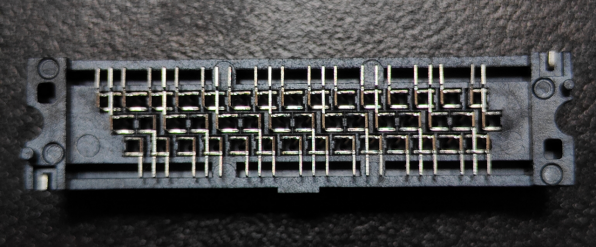

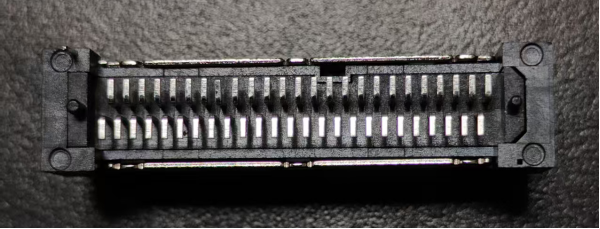

·Measurement requirement: Pin flatness of the product

·Product dimensions: 46mm×12mm (Product 1) and 42mm×10mm (Product 2)

·Scans a single product in 1 second

*Product 1: Physical image

*Product 2: Physical image

Check the environment and installation method.

·Scanning method: The camera is fixed and tilted at approximately 10°, with the test sample moving along a central straight line for scanning and measurement.

·Triggering method: Encoders are used for triggering, outputting a stable AB phase difference signal

·Communication mode: TCP/IP Ethernet

Image capture effect

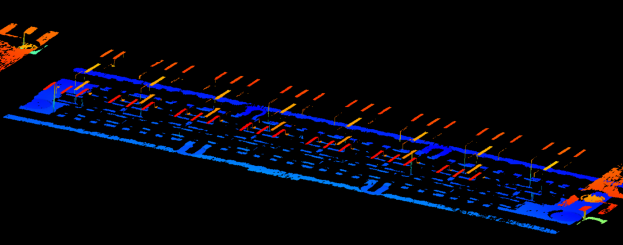

*Product 1

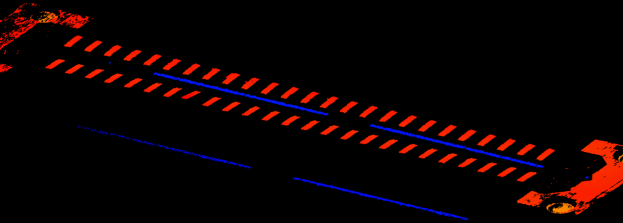

*Product 2

measured data

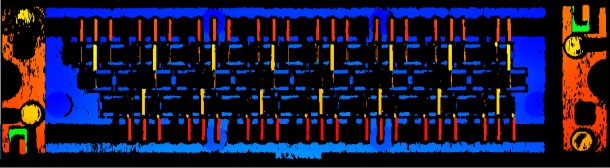

Product 1: Measurement Principle

*Figure 1

*Figure 2

*Figure 3

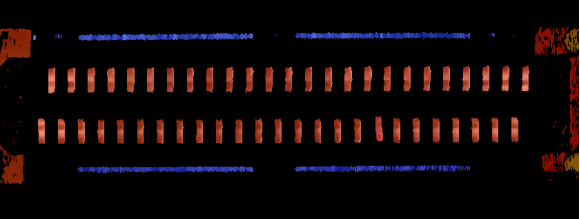

·Depth images captured by the camera (Figure 1)

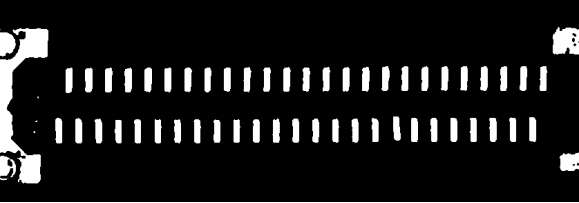

· Image preprocessing: converting depth maps to grayscale (Figure 2)

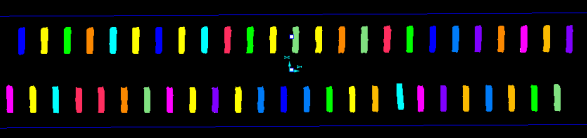

·Segmentation of pin features using grayscale image (Figure 3)

Calculate flatness data

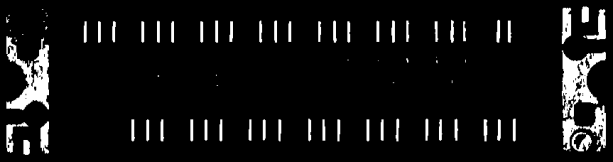

Product 2: Measurement Principle

·Depth images captured by the camera (Figure 1)

·Image preprocessing: converting depth maps to grayscale (Figure 2)

·Segmentation of pin features using grayscale image (Figure 3)

Calculate flatness data

DA

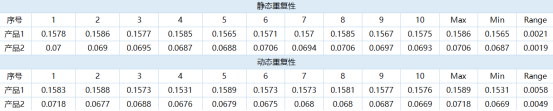

*After 10 tests, both static and dynamic height measurements remained below 0.01mm.

Test conclusion

·This solution delivers comprehensive imaging with sharp feature images. The LVM3320 camera accurately measures product pin flatness within 0.01mm, fully meeting customer specifications.

·The X-axis resolution of the camera ranges from 14.6 to 20.1μm, with a maximum testing speed of 80mm/s

·The camera has a maximum line width of 38mm. One scan can fully cover the product

2025/11/07

2025/11/07