Background knowledge

In the field of automobile manufacturing, die-cast metal parts serve as the "skeleton" for core components such as engine blocks and transmission housings. Their precision directly determines the safety performance and operational stability of the entire vehicle. Among these, the flatness accuracy of bosses and cylindrical holes is a critical indicator affecting the sealing performance and structural strength of the assembled parts.

With the automotive industry's growing demand for' lightweight 'and' high-precision' vehicles, traditional inspection methods have shown limitations in efficiency and accuracy. 3D cameras, with their 3D contour capture capabilities and automation advantages, are emerging as the core solution for upgrading inspection technologies in this field.

Camera Selection

Today, we're excited to showcase the automotive application of the LVM3340 linear laser 3D camera, a new addition to Next Vision Tech's LVM3300 series!

The LVM3340 3D intelligent sensor features a full-frame acquisition rate of 1200Hz, with ROI settings capable of reaching up to 18000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 3μm and capturing every detail, thus meeting the demands of high-precision industrial inspection.

surveillance project

· Measurement of flatness of bosses and cylinders in die-cast parts

·Complete the test within one minute

·Product dimensions: 750*350*55mm

·Dynamic repeatability accuracy must be within 0.03mm

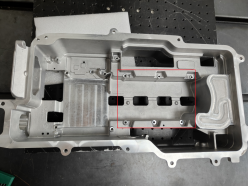

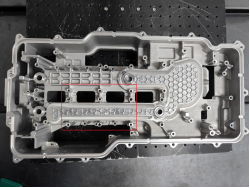

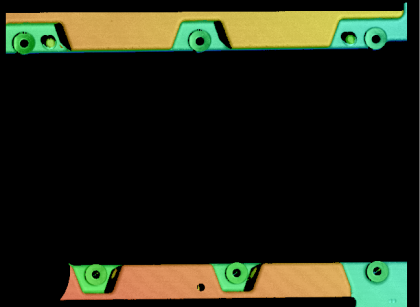

Product front and back view

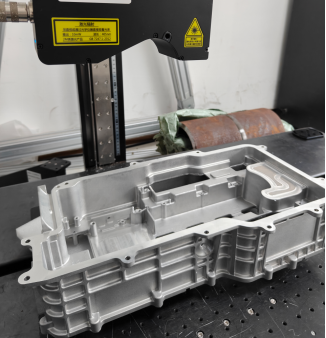

Detection environment and installation method

·Scanning method: The camera is fixed in place, and the test specimen is scanned along a central linear path for measurement.

·Triggering method: Encoders are used for triggering to output stable AB phase difference signals

·Communication method: TCP/IP Ethernet

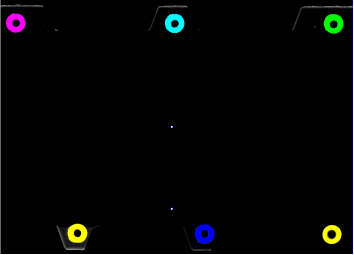

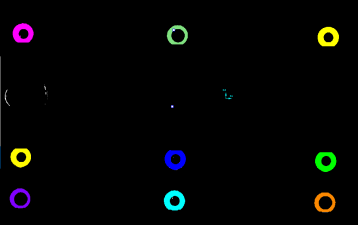

Image capture effect

*The image shows the product front

*Image shows the back of the product

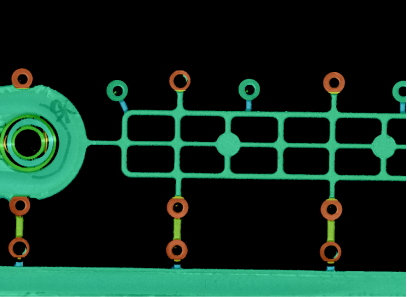

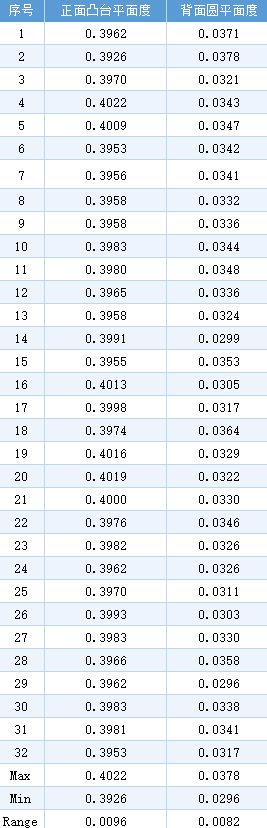

measured data

Product front

· Depth images captured by the camera;

·Preprocess and segment six convex step features, extracting the step surfaces as the measurement area, with the ROI region shown in the figure on the right.

·Calculate flatness and take the average value as the measurement result

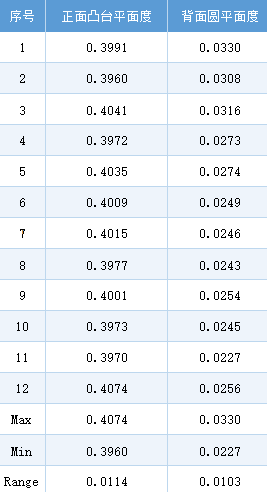

Product back

·Depth image acquired by camera

·Preprocess the segmented cylinder features to extract 9 cylinder surfaces as measurement regions, with the ROI area shown in the figure on the right

·Calculate flatness and take the average value as the measurement result

DA

Static data

dynamic data

*Static repeated image capture test performed 32 times, with static repeatability data error within 0.01 mm; dynamic image capture and release test performed 12 times, with dynamic data error within 0.012mm

Test conclusion

This solution delivers comprehensive imaging results with sharp feature images. The LVM3340 camera enables precise measurement of die-cast part bosses and cylindrical flatness, achieving dynamic repeat accuracy within 0.03mm to meet customer specifications.

·Speed: The camera's test scanning speed is 280mm/s

2025/12/12

2025/12/12